Parker Boiler Operation Manuals

7 to 25HP Steam Boilers The Parker Boiler water tube design offers an extremely efficient, reliable steam boiler built for the long term and ease of maintenance. The Parker Boiler design offers many advantages. Compare ours to the competition. Atmospheric Steam Boiler Certifications All Parker Boiler Steam Boilers are manufactured in accordance with the ASME Power & Heating Boiler Codes and registered with the National Board of Boiler and Pressure Vessel Inspectors. The standard natural gas fired model is furnished as an Under-writers’ Laboratories, Inc. Listed Gas Fired Boiler Assembly and displays their symbol on the nameplate.

Outdoor, propane and Low NOx models are ETL listed. Canadian models are C-ETL List-ed Industrial and Commercial Gas Fired Packaged Boilers certified to CAN/CGA 1-3.1 and UL 795. Low NOx Steam Boiler Certifications All boilers are built in accordance with the ASME Power & Heating Boiler Codes, Sections I & IV. Boilers above 15 PSI are furnished with the “S” Stamp and Trim. Boilers for 15 PSI are normally furnished with the “H” Stamp and Trim.

All Boilers are inspected and registered with the National Board of Boiler and Pressure Vessel Inspectors. All individual gas and electrical controls are Certified or UL Listed. All Low NOx, outdoor, propane and natural gas fired models are ETL Listed as “Industrial and Commercial Gas Fired Packaged Boilers” and certified to UL795.

All units are provided with trim and controls to meet ASME CSD-1 standards for “Controls & Safety Devices for Automatically Fired Boilers”. In addition, all units also meet the standards of the International Conference of Building Officials, the International Association of Mechanical & Plumbing Officials and the Uniform Mechanical Code. Easily Repaired Any steam boiler will likely require retubing sooner or later, depending on care and operating conditions.

Recognizing this, special design consideration was given to this concern. Parker Steam Boiler Tubing is constructed in several individual sections, each connected to the boiler drum and lower Headers by pipe unions.

To replace any section of tubing, it is only necessary to undo the union and remove that section of tubing. It’s possible to temporarily operate the boiler with a tube section completely removed by replacing the unions with pipe caps.

All sections of tubing are interchangeable and so low in cost that many owners purchase an extra section of tubing to have on hand to meet any emergency requirement. Furthermore, the tubing sections on most models can be turned over after several years of operation adding many additional years of service. Advantages (Including Low NOx Models).

Safety. Large Heating Surface. Simplicity. Dry Steam.

Low NOx System. Durable Low NOx Burners. VFD Blowers.

Low Cost Operation. Efficient Operation.

Fast Heat-Up. Accessible Internal Inspection. Ease of Inspection and Repair. Codes.

Heavy Duty Tubes. Heavy Insulated Cabinet.

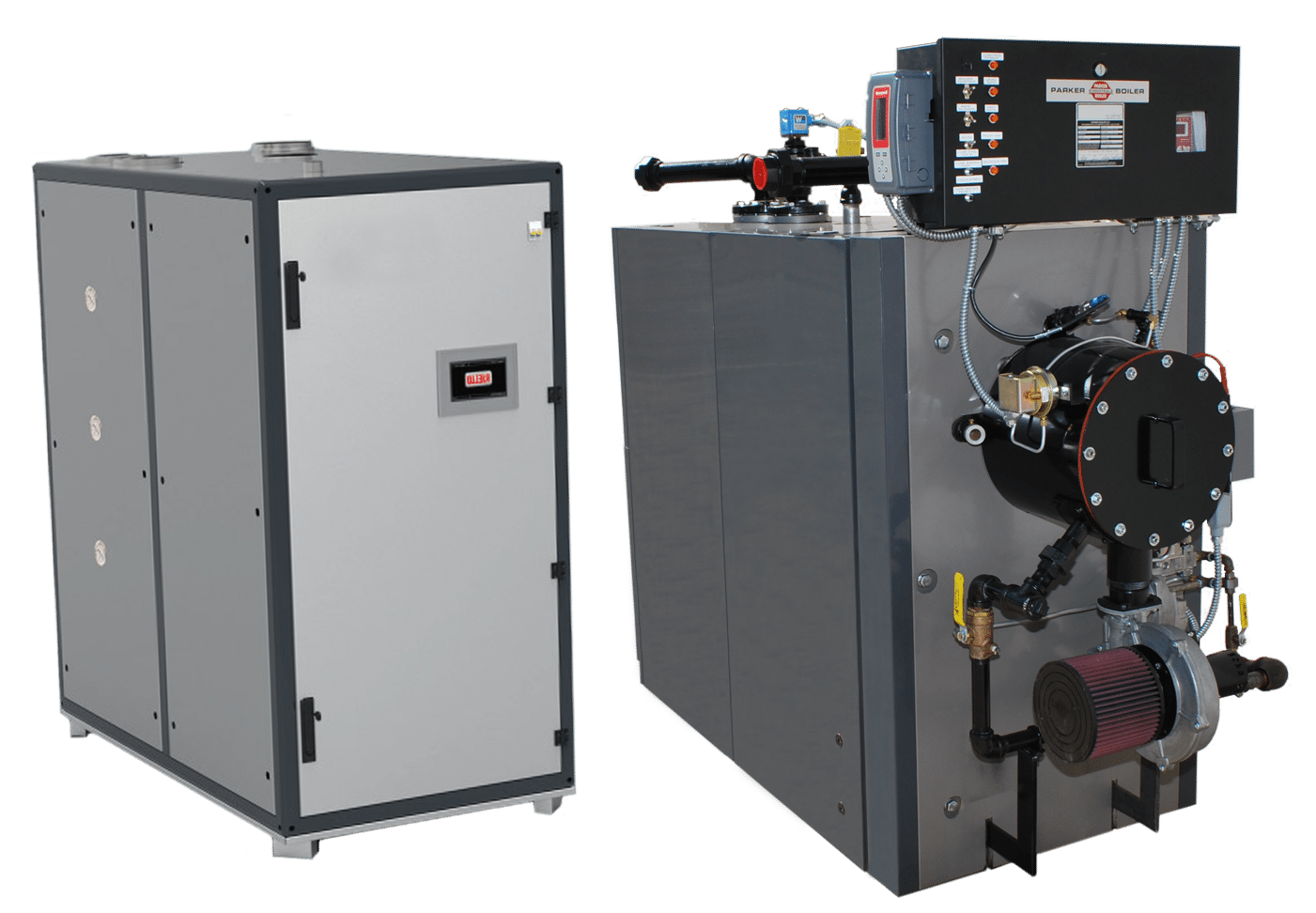

Low NOx Premix Packaged Industrial Packaged Steam Boiler Horizontal Drum Sectional Water Tube 7 to 25HP Gas Fired Low NOx Premix Technology With Heavy Duty Metal Fiber Burners The Parker System offers many advantages of Low NOx and CO Emissions, uniform heat distribution over the entire heating sur-face and improved efficiencies. The boiler incorporates a burner bed of Heavy Duty Metal Fiber Burners (MFB). Through a gas/air premix manifold, the burners may be linked to a fully modulating blower mixer which offers precise control of combustion through the full range of modulation. The Burner System is avail-able on new boilers or for retrofit of Parker. Parker Boiler's System has been field proven on Parker and other types of boilers as a viable, extremely durable, Low NOx, efficient alternative. Parker Boiler Premix Burner System 5 Variable Speed Drive Fan Post Mix System Honeywell Valve/Venturi Low NOx Steam Boiler Insert.

The Jensales Team is excited to bring you this Parts Manual for the Komatsu PC120 Excavator. A historically accurate parts manual is essential when ordering. Komatsu 120 specifications. Find great deals for Komatsu Pc120-6 Parts Manual Book Catalog Hydraulic Excavator Guide PEPB008206. Shop with confidence on eBay! Find great deals for Komatsu Pc120-6 Parts Manual Book Catalog Hydraulic Excavator Guide PEPB008205. Shop with confidence on eBay!

Boilers up to 3,120,000 BTU The Parker water tube design offers an extremely efficient, reliable Water Wall Hot Water Boiler built for the long term with ease of maintenance. The Parker design offers many advantages. Compare ours to the competition. Power Burner Water Wall Hot Water Boiler Certifications ('R' Model) All Parker Hot Water Boilers are manufactured in accordance with the ASME Heating & Power Boiler Codes, and registered with the National Board of Boiler and Press re Vessel inspectors. The boiler, burner and controls are prewired, factory tested and Listed by a Nationally Recognized Testing Laboratory as Gas, Oil or Combination Gas/Oil Fired Boiler Assemblies to UL Standard 795 & CAN/CGA STD 1-3.1. Oil Fired boilers are Listed per UL 726. Low NOx Water Wall Hot Water Boiler Certifications ('RL' Model) All Parker Hot Water Boilers are manufactured in accordance with the ASME Heating & Power Boiler Codes, registered with the National Board of Boiler and Pressure Vessel inspectors.

The boiler burner and controls are prewired, factory tested and Listed by a Nation-ally Recognized Testing Laboratory as Gas Fired Boiler Assemblies to UL Standard 795 & CAN/CGA STD 1-3.1. Safety Our ASME tube bundle is extremely flexible and offers a long life with a 25 year warranty against thermal shock. No Parker Boiler has ever been known to experience an internal explosion. Advantages (Power Burner and Low NOx Models). Safety. Large Heating Surface.

Sealed Combustion. Efficiency. No Thermal Shock. Low NOx.

VFD/Premix System. Ultra Low Nox Option. Efficient Operation.

Low Excess Air Levels. Fits Through 36' Door.

Ease of Inspection and Repair. Lighter Weight. Heavy Duty Tubes. Heavy Insulated Cabinet.

Water Wall Power Burner Direct Fired Hot Water Boiler Bent Steel Water Tube Parker Boiler 'R' Model 500,000 to 3,080,000 BTU Power Gas, Light Oil or Combination Fired Water Wall Power Burner Hot Water Boiler ('R' Model) A highly efficient power burner is provided. The burner and controls are factory wired, tested and listed by Underwriters Laboratories. Boilers are provided with two stage or modulation firing. The Power Flame Model CG gas burner presents optimum state-of-the-art design for maximum combustion efficiency and operating dependability. These packaged combustion systems will fire natural gas and a full range of waste or other gaseous fuels. The Model CG HTD (High Turndown) will fire natural gas at turndowns up to 10 to 1.

Parker Boiler Service Manual

The flame retention firing head incorporates the nozzle mix multiport combustor and unique air sandwich design to produce full range stable performance in both positive or negative combustion chamber environments. Operating system adjustments have been minimized to provided trouble free start up and operating performance. Water Wall Power Burner Hot Water Boiler Insert 204R Series Hot Water Boiler Power Gas, Light Oil or Combination Fired. Water Wall Low NOx Premix Direct Fired Hot Water Boiler Bent Steel Water Tube Parker 'RL' Models 672,000 to 3,120,000 BTU Gas Fired Parker Boiler Premix Burner System The Parker System consists of a Heavy Duty Cylindrical Metal Fiber Burner (MFB). Through a gas/air premix manifold, the burner may be linked to a fully modulating blower mixer which offers precise control of combustion through the full range of modulation.

Parker uses a variety of premix gas/air mixing & delivery systems for it’s “L” System boilers. Parker’s Low NOx Systems are typically designed for a 20 or 30 ppm level at 3% O2, however, special 12 ppm Low NOx boilers are also provided. In all cases, a Premixed gas/air is distributed to the burners by a manifold. By precisely controlling the gas/air ratio provided to the burners, Low NOx emission & efficient clean combustion is obtained. Parker Boiler Premix Burner System 4 Variable Speed Drive Fan Post Mix System Siemens SKP - Controller.